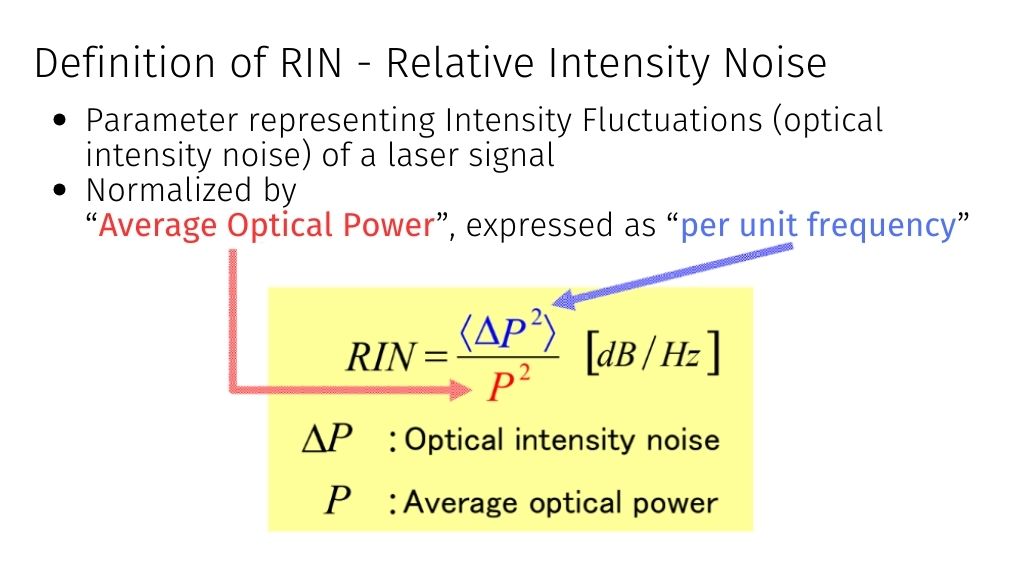

What is RIN?

RIN stands for Relative Intensity Noise.

RIN is a parameter that represents fluctuations in the intensity of laser light.

Fluctuations in the intensity of laser light are due to the fact that the wavelength (energy) of the photons emitted from the laser is not constant.

RIN is defined as the fractionation of the laser output intensity per unit frequency relative to its average value.

RIN directly affects the signal-to-noise ratio (SNR) in optical communications; a lower RIN improves the SNR of optical communications and increases the transmission capacity per unit bandwidth. For this reason, RIN has become increasingly important in supporting the recent increase in optical communication capacity.

What is Relative Intensity Noise (RIN) Measurement System?

A RIN measurement system refers to a device that measures the intensity noise characteristics of laser light and quantitatively visualizes the results.

To objectively evaluate noise characteristics, RIN measurement results are displayed as a spectrum.

What is the role of Relative Intensity Noise (RIN) Measurement System?

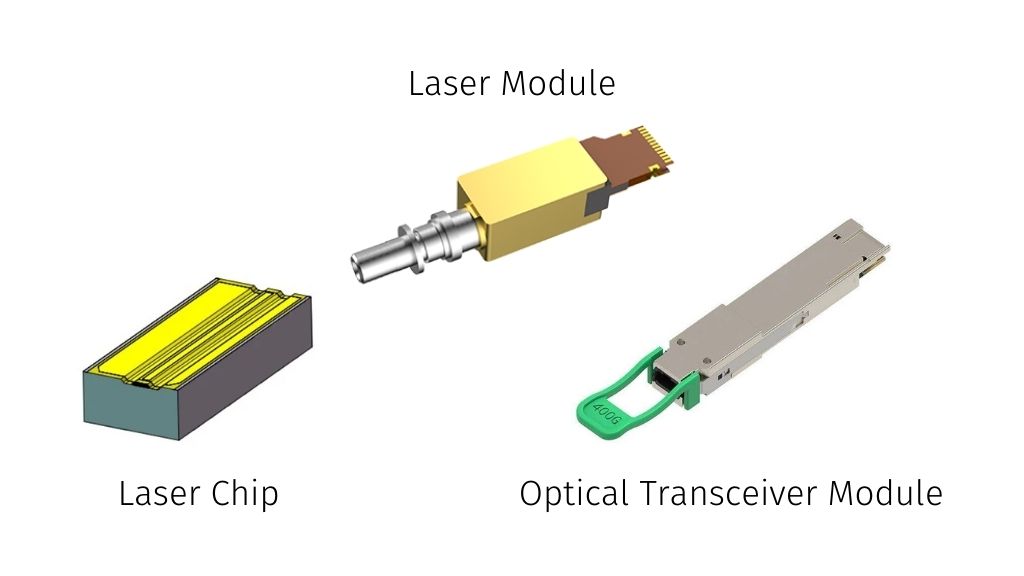

RIN measurement systems have become an indispensable tool in the design, evaluation, and verification of optical communication systems.

They play an important role in the design and development phase of lasers, evaluating the performance of newly designed lasers and providing feedback to improve their quality.

The data obtained from the measurements allows us to understand the causes of laser intensity noise and develop strategies to reduce it.

It is also important to understand the impact of laser intensity noise on the overall performance of the optical communication system. By using a RIN measurement system, it is possible to capture the intensity noise of lasers and improve the transmission capacity and reliability of optical communication systems.

In recent years, low power consumption of lasers for optical communications has become an important issue. Since RIN of lasers is a trade-off for current consumption, RIN measurement systems have gained increasing weight in the design of both lasers and the communication systems that use them, in order to achieve both low power consumption and high communication capacity.

During the manufacturing phase of a laser, RIN measurements can verify that the laser's intensity noise is within acceptable limits and conforms to product specifications. Evaluation with a a RIN measurement system is an essential step in assuring the quality of the laser and maximizing its performance.

Types and Comparison of Relative Intensity Noise (RIN) Measurement System

There are two main types of RIN measurement systems.

One is to measure it as a spectrum in the frequency domain, and the other is to measure it as a transient characteristic in the time domain. Each method is explained in detail below.

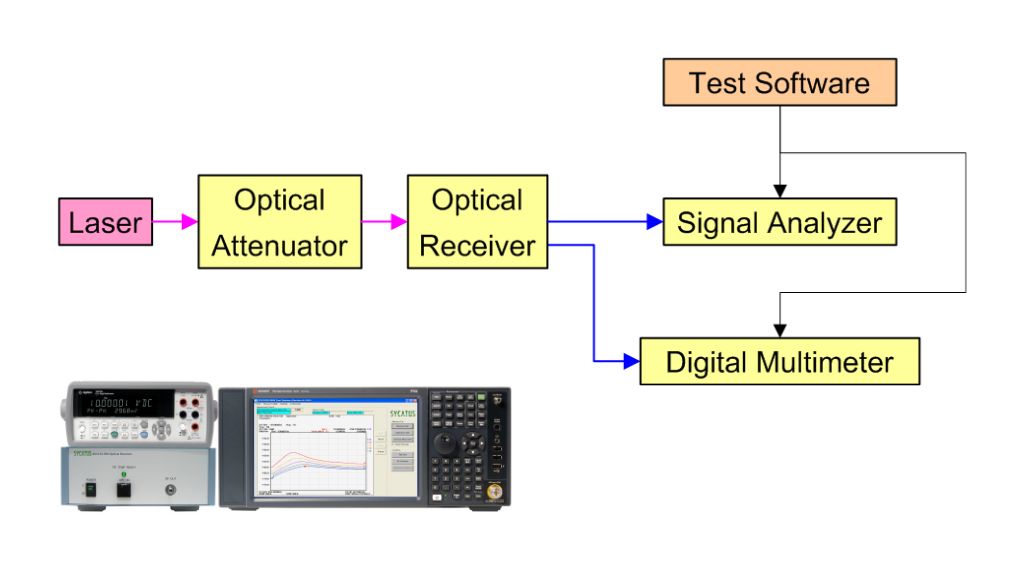

Structure of Spectral Relative Intensity Noise (RIN) Measurement System

The main components of a spectral RIN measurement system are an optical receiver, a signal analyzer, a digital multimeter and analysis software.

The laser light is converted into an electrical signal and amplified by the optical receiver, then input to the signal analyzer. A digital multimeter measures the photocurrent received by the optical receiver. The spectrum signal obtained by the signal analyzer is numerically processed by the analysis software together with the photocurrent value to obtain the RIN as a spectrum.

This type of system provides detailed RIN characteristics as a spectrum. Moreover, by applying a filter characteristic to the RIN spectrum, the total RIN characteristic of any bandwidth can be obtained.

On the other hand, only unmodulated laser light (CW light) can be measured by this system. In addition, the photodetector and signal analyzer must be sufficiently low noise, and the analysis software must be based on physical principles to calculate accurately. The entire system must be calibrated precisely to improve the accuracy of the measurement.

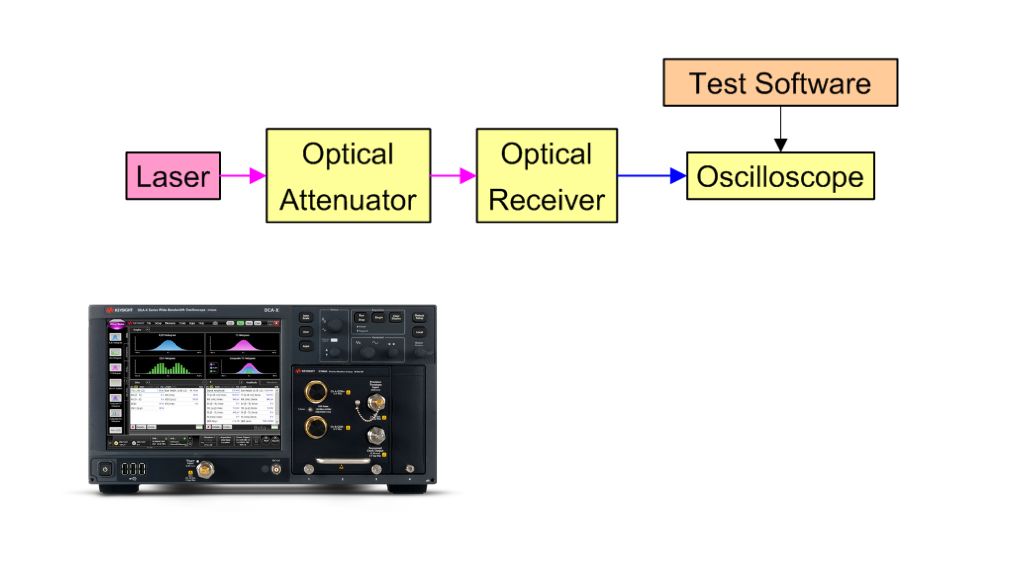

Structure of Transient Characteristic Relative Intensity Noise (RIN) Measurement System

The main components of a transient characteristic RIN system are an optical receiver, an oscilloscope and analysis software.

The laser light is converted into an electrical signal by the photodetector and captured in time domain by the oscilloscope. From the statistical distribution of the transient waveforms, the RIN is calculated using analysis software.

This type of system can also measure RIN for modulated laser signals. However, the amplitude resolution of oscilloscopes is often insufficient for RIN measurements, making them unsuitable for evaluating the very low RIN characteristics required by recent optical communication systems. Also, since only the average of the RIN within the bandwidth of the system can be obtained, sufficient information is not available to analyze the RIN of lasers in detail. The bandwidth of the measurement is limited to that of hardware and the frequency characteristics cannot be compensated.

Relative Intensity Noise (RIN) Evaluation

The results of RIN are usually expressed in dB/Hz. The lower the value, the lower the noise of the laser.

The required RIN performance for a laser depends on the applicable communication standard. Recent optical transceiver standards require RIN characteristics below -140 dB/Hz.

Also, the measured RIN depends on the frequency of the spectrum. The RIN must be evaluated in the same bandwidth as the transmission system in which the laser is used. For this reason, the RIN needs to be evaluated in a wide bandwidth of up to 50 GHz.

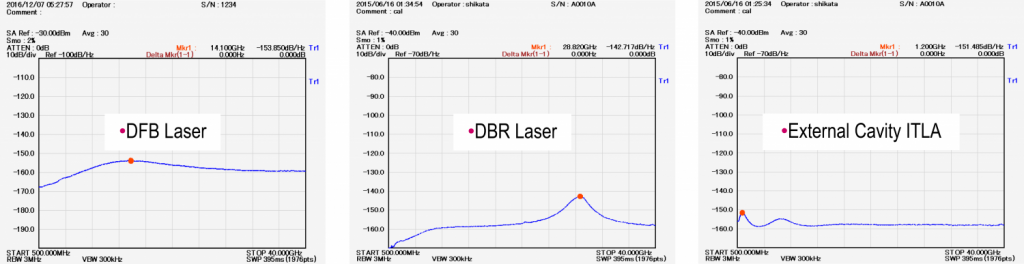

The spectral shape of the RIN depends on the structure of the laser. The effect of changes in laser design and manufacturing parameters on the RIN needs to be analyzed.

The RIN is strongly affected by external electrical noise and back-reflected light to the laser. These situations can be discriminated by the shape of the RIN spectrum.

SYCATUS products can solve your relative intensity noise (RIN) measurement problems!

RIN measurement is an essential process to ensure laser performance and requires understanding and proper operation.

However, advanced expertise and technology are required to correctly measure RIN.

The A0010A RIN measurement system from SYCATUS uses a high-sensitivity, low-noise optical receiver and Keysight Technologies' high-performance X series signal analyzer to evaluate the RIN spectrum over a wide measurement bandwidth of 50 GHz, the world's largest.

SYCATUS' proprietary system-wide calibration technology provides superior measurement accuracy and repeatability.

We hope you will utilize our A0010A measurement system for your laser development, manufacturing, and evaluation.

Conclusion: The Role of Relative Intensity Noise (RIN) Measurement System and Its Interpretation

RIN measurement is an important process for evaluating laser performance and assuring its quality. However, it is a challenging measurement item because the structure and performance of the measurement system greatly affect the evaluation results and requires specialized knowledge and techniques.

In addition, for the evaluation of RIN measurement results, not only the average value but also the frequency dependence is an important point to be considered.

Selecting a measurement system with appropriate functions and accurate numerical calculations will enable you to make highly accurate measurements and improve the performance of your laser.

SYCATUS' A0010A Relative Intensity Noise measurement system allows you to accurately and easily evaluate the RIN performance of your laser without requiring expertise in RIN measurement or going through a complicated measurement process.

This not only saves the user time and effort, but also greatly improves the quality of the laser. We hope you will take advantage of the A0010A RIN measurement system.

In the next column, we will introduce “Can I build my own optical noise measurement system?”. Please stay tuned.

Feel free to contact us.

As a pioneer in measurement in the field of optical communications and optical sensing, SYCATUS has been providing integrated hardware and software systems for measurement for over 20 years.

We will continue to provide innovative optical measurement technologies developed on the basis of expertise, uniqueness, and accuracy to the world.

We also provide expert advice on a wide range of optical measurement questions and concerns regarding the installation of system equipment.

Our experts are available to help you solve your optical measurement problems.